A proven efficient and proactive operator, KRL has an innovative exploration and production staff with the capability and experience to operate safely and cost-effectively in diverse and challenging settings. We have conducted successful operations throughout the southern oil rich region of Nigeria.

Kesiteg Resources Limited has conducted operations in partnership with many of the major Oil and Gas companies within and outside the country and earned the respect of the industry as an experienced, capable and cost-effective operator.

We provide the full spectrum of mechanical, specialty welding, high-temperature repair and inspection (HRI), and upstream oil-field services through nested maintenance, turnaround or construction services. We have a solid track record across all major work scopes, including on FCC, Hydrocrackers, Hydrogen Plants, Alkylation units, Cokers, Crude units, Reformers and Sulphur units.

KRL site maintenance services include preparing the site pre-production, maintaining the site during production and site beautification post-production. Performance each phase of tasks is done in order to maintain the lease site, its structures and surrounding areas. This includes ensuring the property is secured to prevent trespass of unauthorized personal and wildlife onto the site in order to prevent property loss and damage.

KRL offers full engineering design, build, and installation of these facilities along with the capability to operate and maintain them, allowing you to achieve production targets while minimizing capital spend.

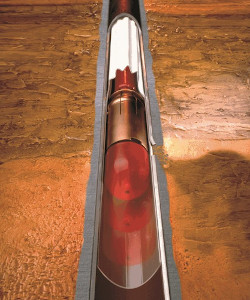

For wells where more data is needed to define the reservoir characteristics, or to better define the produced fluids in order to establish design parameters for production facilities, we apply traditional well testing equipment for an extended well test. The opportunity exists to store produced oil for later sale, such that the cost of the extended test may be offset by the sale of oil from production.

The ability to implement your process facility specifications begins by creating a true partnership with you from the beginning. During the initial front-end engineering and design stage, we focus on the design requirements. From the initial requirements, we have the ability to “fast-track” facilities specially designed to meet requirements or provide facilities around standard process modules for well control, separation, fluid conditioning, and disposal

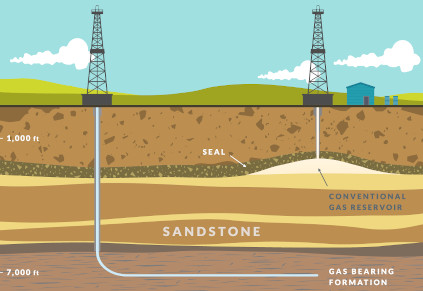

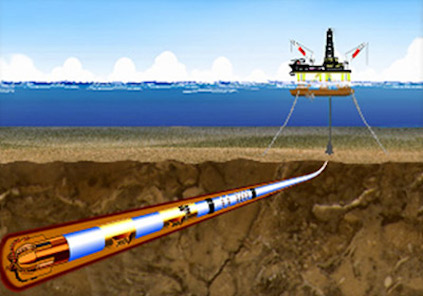

KRL drilling and completion engineers work closely with clients’ geologists and reservoir engineers to prepare cost-effective well designs that reach objectives and ensure maximum productivity. We have successfully designed and managed drilling projects for horizontal and extended-reach wells, deep-water sub-sea wells, reservoirs with complex geological formations, and urban drill sites.

We also provides production enhancement activities, undertaking facility and well economic analyses, well-bore reviews and management of slot recovery projects.

Quality assurance and quality control services from KRL – assure the quality of all materials, structures, components and systems utilized in the construction, manufacturing and operation of your industrial facilities.

When it comes to your industrial facilities, the quality of all equipment, materials, structures and components is subject to strict regulations and standards. Our quality assurance and quality control services help you ensure compliance with all contractual specifications, mandatory regulations and quality standards.

We provide an equipment and material procurement and supply service to the Oil and Gas industry throughout Nigeria. Procurement in the Oil & Gas Industry has become an essential service in today’s competitive marketplace. Our role is to find and supply all the manufactured goods associated with the exploration and delivery of oil and gas. Our customers expect an exceptional level of service and we fulfil that expectation by delivering a reliable, honest, diligent and conscientious service that meets their specific demands.

The following list provides typical examples of the type of equipments we supply:

KRL chemicals and additives enable oilfield service and technology providers to excel in increasingly challenged environments. KRL delivers products to all the major application segments in the oilfield, including drilling, completion, stimulation and production. We bring value, whether through development of tailored solutions for demanding applications or by delivering quality product efficiently and consistently.

We are one of the country's leading suppliers of pine chemicals, including tall oil fatty acid, tall oil rosin, distilled tall oil, terpenes and polyamides.

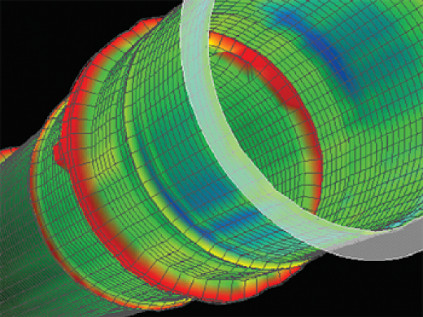

Meeting the fundamental requirement of a fully martensitic microstructure even at large pipe wall thickness requires good hardenability. Cr and Mn are the main alloying elements used to produce good hardenability in conventional heat-treatable steel. However, the requirement for good sulphide stress cracking (SSC) resistance limits their use. Mn tends to segregate during continuous casting and can form large MnS inclusions that reduce hydrogen induced cracking (HIC) resistance. Higher levels of Cr can lead to formation of Cr7C3 precipitates with coarse plate-shaped morphology, which act as hydrogen collectors and crack initiators. Alloying with Molybdenum can overcome the limitations of Mn and Cr alloying. Mo is a much stronger hardener than Mn and Cr, so it can easily recover the effect of a reduced amount of these elements.

Traditionally, OCTG grades were carbon-manganese steels (up to the 55-ksi strength level) or Mo-containing grades up to 0.4% Mo. In recent years, deep well drilling and reservoirs containing contaminants that cause corrosive attack have created a strong demand for higher strength materials resistant to hydrogen embrittlement and SCC. Highly tempered martensite is the structure most resistant to SSC at higher strength levels, and 0.75% is the Mo concentration that produces the optimum combination of yield strength and to SSC resistance(1).

Drilling and exploration have never been more challenging. Drilling equipment must operate in harsher and more remote environments than ever before.

KRL provides integrated solutions for the maintenance, repair, overhaul and upgrade rotating equipment for both the oil & gas and power generation industries. KRL has the necessary experience to manage your asset by providing all support services that will enable safe, reliable and cost effective operation. You can focus on managing your business while we take responsibility for the operation and system reliability of your rotating equipment, applying our industry leading technical expertise, KRL procedures and management processes.

We support a wide range of equipment, including:

Industrial instrumentation is used to control and monitor conditions including temperature, pressure and fluid levels in processing facilities, oil refineries, petrochemical plants, oil and gas pipelines, and distribution operations. Common applications of oil and gas instrumentation include monitoring the presence of flammable and combustible gases in production and storage areas and monitoring emissions for pollution control. Instrumentation is also used for monitoring and controlling flow in delivery systems.

There are two types of instrumentation used in equipment monitoring: input and output. Input instruments are used to monitor or measure temperature, flow, pressure and levels in equipment including transport pipes and vessels. Output instruments, on the other hand, include controls and alarms that display readings or provide an alert to warn of potentially hazardous situations.

The three primary components of industrial instrumentation are sensors, transducers and transmitters.

KRL provides safe, effective and efficient drilling services throughout major onshore fields in the south-south region of Nigeria.

We deliver the wellsite safety you expect and the productive drilling

days your bottom line requires. Communication throughout the project is

the starting place for both.

Long-time clients recognize that KRL can maximize their wells’ success

through early and ongoing collaboration. From drilling crews to the

president of drilling services, we use our experience — as requested —

to help streamline operations, reduce your drilling costs and shrink our

time on site. We take personal responsibility for ensuring maximum

safety and minimum non-productive time on your well.

Smart, efficient processes underscore our commitment to responding quickly and making drilling operations run smoothly. A robust preventive maintenance program on our rigs is one example of how we accomplish that. Another is daily electronic reports on each project. Yet another is sharing information daily across our divisions and geographic regions to alert us to any rig or equipment issues that could affect your project.

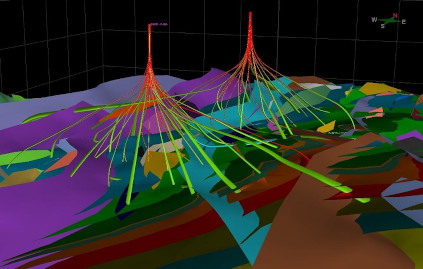

Kesiteg Resources Limited strives to provide you with the best possible service and support for your well-planning and engineering needs. By utilizing the top software in the industry, you can count on customized well plans and detailed anti-collision reports with exports tailored to meet your individual requirements. Our team provides support from start to finish for each well drilled.

When required, our experienced engineering team can prepare hydraulics analysis and detailed torque & drag reports pre and post run to help you configure the right tools for any job. Select the optimum rig and equipment, string components, and fluids to drill any type of well (onshore, offshore, deep water, high-pressure/high-temperature, 3D directional profiles, horizontal, and extended reach). Model pipe strings to define optimum windows of operation during the design and execution phases of your well. Anticipate risks and know how to drill faster without compromising the safety of the operation.

KRL is able to deliver even more value to customers thanks to our integrated approach to serving Oil and Gas transmission clients. Because we are able to construct the transmission facilities and fabricate the piping and equipment we are able to act as a single point of contact.

Fast, high-quality data for accurate geosteering and formation evaluation. Increase ROP, improve wellbore stability and hole quality, and optimize well placement and reservoir exposure for maximum production—faster.

As the industry expert in LWD technology, KRL creates advanced LWD services that acquire high-quality data for accurate geosteering and more-informed formation evaluation, so you can work proactively as you drill.

Providing wellbore position, drillbit information and directional data, as well as real-time drilling information, KRL uses gyroscopes, magnetometers and accelerometers to determine borehole inclination and azimuth during the actual drilling. The data is then transmitted to the surface through pulses through the mud column (mud pulse) and electromagnetic telemetry. Decoded at the surface, the data can also be transmitted to an offsite location immediately.

With such precise wells being drilled, KRL aids drilling engineers with real-time information so that they can make important decisions while drilling. Geosteering is a relatively new concept of positioning wells according to the geological features in the reservoir obtained through KRL. Now, video is even available to help in the process.

KRL's Cased-Hole Logging Services enable you to reduce the risk of costly interventions and Non-Productive Time (NPT) while increasing production efficiency. With a breadth of services for well performance evaluation, integrity, and recovery troubleshooting, KRL enables a whole new level of performance for your onshore, offshore and deepwater applications.

KRL's Cased-Hole Wireline Logging Services have a number of advantages including:

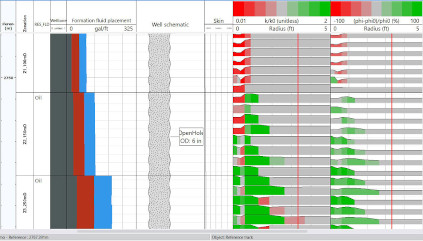

A treatment designed to treat the near-wellbore reservoir formation rather than other areas of the production conduit, such as the casing across the production interval, production tubulars or the perforations. Matrix stimulation treatments include acid, solvent and chemical treatments to improve the permeability of the near-wellbore formation, enhancing the productivity of a well. Matrix stimulation is a process of injecting a fluid into the formation, either an acid or solvent at pressures below the fracturing pressure, to improve the production or injection flow capacity of a well.

The goal of a matrix treatment is different in sandstones than in carbonates. In sandstones, matrix treatments restore or improve the natural formation permeability around the wellbore by removing formation damage, by dissolving material plugging the pores or by enlarging the pore spaces. In carbonates, matrix stimulation creates new, highly conductive channels (wormholes) that bypass damage

All wells require intervention at some time in their productive life. Kesiteg Resources Limited expertise and technology enables us to provide innovative and effective well intervention solutions on multiple conveyances. All solutions are geared towards maximizing production performance and reducing overall operating costs without losing focus on providing the highest quality of service to our customers.

This allows operators to perform downhole work by deploying mechanical intervention tools or well diagnostics to evaluate or maintain optimal well performance and extend the productive life of the well. We are able to perform these quality services by using experienced, highly trained personnel committed to designing and executing the most sophisticated operations in the industry to provide the finest and safest prejob, post-job, and onsite service.

Our vast array of fishing systems and tools—applied with our industry-leading fishing knowledge—remove wellbore obstructions safely and efficiently, greatly reducing the cost associated with wellbore problems.

We invented many of the fishing, milling, cutting, specialty tools, and techniques used in cased hole, open hole, and thru-tubing intervention. Decades of field experience and our continuous investment in research and engineering have resulted in innovative solutions to the problems that impede production and interrupt operations. From smart-intervention tools to accessory equipment that enhances performance, we have the products and services to meet your fishing challenge.

A whipstock adapted for insertion into a wellbore through a tubing string having a smaller diameter than the wellbore casing or the open hole portion of the wellbore includes a setting mechanism comprising extendable legs which engage the wellbore wall to bias the whipstock into a position of inclination of the whipstock guide surface relative to the wellbore axis. The setting mechanism includes an actuating rod which may be actuated by a conventional downhole tool setting device to extend and retain the legs in their extended position. Cooperating ratchet means and tensionable couplings on the setting mechanism including a frangible coupling part permit actuation of the whipstock to its set position and retrieval of the setting device. The whipstock is releasable from the setting device by an adaptor having cooperating ball keys engageable with an adaptor actuating shaft and the upper end of the whipstock body.

Kesiteg Resources Limited provides safety services for all facets of the Oil and Gas industry, including upstream, midstream, and downstream parts of the process. We can work with owners or contractors to develop best in class safety systems that increase compliance and minimize injury.

Field Development Planning is the daunting process of evaluating multiple development options for a field and selecting the best option based on assessing tradeoffs among multiple factors:

KRL has an experienced team of consultants with integrated field development experience around the world. Our team uses Front End Loading and Rapid Prototyping to formulate FDPs efficiently:

KRL's experience includes formulating multiple large-scale integrated field development plans around the world.

We help organizations by combining deep industry expertise with our state of the art tools and solutions: - Cost Engineering Services – Cost Estimating & Validation, Scheduling, Cost Control, Benchmarking, Risk Management.

Oil and gas companies operate in an environment that is under financial, competitive and regulatory stress. Conflicting legal and regulatory frameworks, pervasive contractual disputes and high market volatility generate increasing challenges to operating management. KRL bring oil and gas industry operating experience and litigation support expertise to companies and their counsel.

We provide a unique combination of seasoned managerial and executive experience with insights gained from years of dispute management, damages analysis, public policy analysis and expert testimony.

Kesiteg Resources Limited utilize proven techniques to coach and train all parties involved to insure that Safety Observation Reports are a key tool to improve refinery workplace safety. Refinery Safety Observation Reports are used as an informal way to conduct observations of the job site to identify, not only the negative, but the positive acts or conditions as they relate to working site safety. All this is geared towards ensuring a good working atmosphere for workers and clients.